A Comprehensive Guide to Screen Printing: Unveiling the Step-by-Step Process

A Detailed Walkthrough of the Printing Process

Dive into the intricate world of screen printing, a versatile technique widely employed across various industries. This method involves pressing ink through a stenciled mesh screen to bring designs to life, an art form so ubiquitous that you may have unknowingly encountered screen-printed items in your everyday life. Whether referred to as serigraphy or silk screen printing, these terms encapsulate the same fundamental approach, offering a detailed overview of a captivating process.

- Applications of Screen Printing:

The realm of screen printing extends beyond vibrant canvases and posters; it encompasses the printing of fabrics, textiles, wood, metal, plastic, and even glass. This adaptability makes screen printing an ideal choice for creating an extensive range of custom apparel and products, showcasing its significance in various creative and industrial sectors.

- The Screen Printing Process:

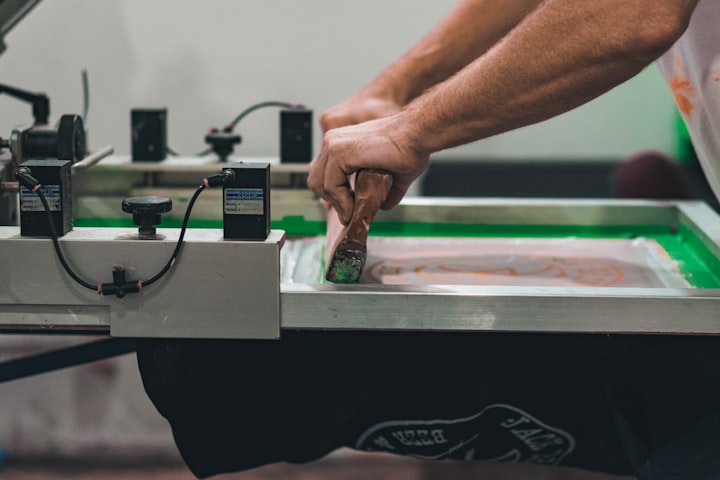

At its core, screen printing involves the transfer of a stenciled design onto a flat surface using a mesh screen, ink, and a squeegee. While the term 'silk testing' or 'silk screen printing' often describes the process, the methods of stencil creation can vary. Techniques range from using masking tape or plastic to cover specific screen areas to painting the stencil onto the mesh with screen blockers like adhesive or lacquer. Another method involves employing a light-sensitive solution to craft a pattern, akin to developing a photograph.

- Colors and Customization:

The versatility of screen printing shines in its ability to accommodate single or multiple colors in a design. For multi-colored items, distinct screens are utilized to apply each layer of ink, allowing for the creation of intricate and highly customizable patterns. This level of customization makes screen printing a favored method for producing distinct garments, be it sports team uniforms or corporate attire.

- Advantages of Screen Printing:

One of the primary reasons for the widespread use of screen printing lies in its capability to produce vibrant colors, particularly on darker materials. The layered application of ink not only adds visual appeal but also provides a tactile quality to the prints. Furthermore, the method's efficiency in reproducing designs multiple times makes it invaluable for creating consistent and identical garments, catering to the needs of sports teams or businesses requiring uniformity.

Step-by-Step Screen Printing Process:

- Design Creation: The process kicks off with the creation of the desired design, which is then printed onto an acetate film.

- Screen Preparation: A mesh screen is chosen based on the design's complexity and the texture of the fabric to be printed. The screen is coated with a layer of light-reactive emulsion, which is then exposed to bright light.

- Emulsion Exposure: The acetate sheet containing the design is carefully laid onto the emulsion-coated screen and exposed to intense light. This exposure solidifies the emulsion, with the areas covered by the design remaining in a liquid state.

- Pattern Development: After a set exposure time, the screen is washed, removing the unhardened emulsion and leaving an exact imprint of the design on the screen.

- Product Preparation: The prepared screen is placed onto the printing machine, with the item to be printed laid flat beneath it.

- Ink Application: Ink is added to the top end of the screen, and a squeegee is employed to draw the ink across the screen's entire length. This action presses the ink through the open areas of the stencil, imprinting the design onto the product beneath.

- Drying and Finishing: The printed product undergoes a drying process, typically through a dryer, ensuring the ink is cured to create a smooth, colorfast finish. The final product is meticulously inspected and washed to remove any residual ink before reaching its new owner.

FAQs About Screen Printing:

- Will screen printing ink wash out?

If a garment is properly screen printed using heat-treated washable ink by a skilled professional, the design should not wash out. Following the manufacturer's instructions for ink setting, including the correct drying temperature and time, is crucial for achieving a lasting, washable product.

- What is the difference between screen printing and digital printing?

Screen printing involves transferring a design through a stenciled mesh, whereas direct-to-garment (DTG) digital printing employs a specialized fabric printer, similar to an inkjet printer, to transfer images directly onto fabric. Digital printing is known for its suitability in producing intricate or colorful designs in smaller batches, as it requires minimal setup compared to screen printing. Additionally, digital printing is ideal for creating photographic or detailed designs, albeit with a different color intensity compared to screen printing.

About the Creator

Screen Print Direct

Screen Print Direct: Partnering with printers & artists to achieve goals. A diverse team of printers, artists, students, & entrepreneurs with BIG ambitions. We aim to help YOU succeed.

Comments

There are no comments for this story

Be the first to respond and start the conversation.