Mastering the Craft: A Comprehensive Guide to Screen Printing Equipment and Techniques

Exploring Every Aspect of Screen Printing for Unrivaled Precision and Results

If achieving a clean and sharp print is your goal, having the right screen printing equipment is crucial. In this comprehensive guide, we will delve into each component of screen printing machinery, outlining their functions in the printing process. From the screen printing press to the nuances of inks, silkscreens, squeegees, and washing stations, this guide aims to equip you with the knowledge needed to master the art of screen printing.

Screen Printing Press:

At the heart of efficient screen printing lies the screen printing press. While it's possible to screen print with just a mesh screen and a squeegee, many professionals opt for a press due to its ability to print numerous items more efficiently. The press securely holds the screen in place between prints, streamlining the process of switching out the items being printed.

Three main types of presses exist: manual, semi-automatic, and automatic. Manual presses, operated by hand, are more labor-intensive. Semi-automatic presses are partially mechanized, requiring human input to switch items. On the other hand, automatic presses are fully automated, demanding minimal human involvement. Larger-scale operations often choose semi- or fully automated presses for faster, more efficient printing and reduced errors. Smaller businesses or hobbyists might find a manual table-top press better suited to their needs.

Inks:

Beyond the spectrum of colors, choosing the right ink is a crucial decision in screen printing. Various specialty inks, including glittery, texturized, or smoke inks, can be used to create unique finishes. The choice of ink also depends on the material being screen printed, as some inks adhere better to specific materials. For garments, a type of ink that becomes machine washable after heat treatment is commonly employed, ensuring a colorfast, long-wearing result that can withstand repeated use.

Silkscreen:

In the realm of T-shirt screen printing machines, the silkscreen is a pivotal component. Traditionally crafted from silk thread, contemporary silkscreens often utilize polyester fabrics for cost efficiency while maintaining performance. The silkscreen is a frame with mesh stretched over it, and the mesh's thickness and thread count can be tailored to suit the texture or material of the surface being printed. After coating the screen with a solution and exposing it, the screen becomes a reusable pattern for the printing process.

Squeegee:

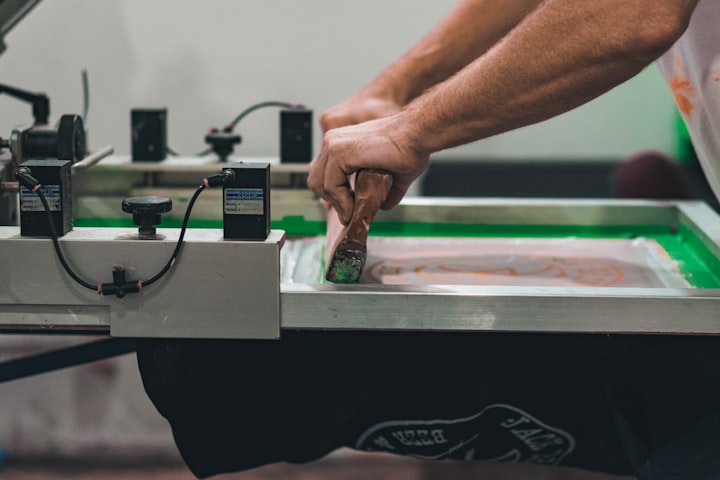

The squeegee, a seemingly simple tool, plays a vital role in the screen printing process. It consists of a rubber blade attached to a handle and is used to press ink through the mesh screen and onto the surface being printed. The choice of a squeegee is not arbitrary; the size and rubber blade hardness should match the screen frame size for optimal coverage. A more robust rubber blade is suitable for intricate designs, ensuring even coverage in every nook and cranny of the stencil, while a softer, more yielding rubber blade is preferred for less detailed designs or fabric printing.

Washing Station:

Post-printing, screens need thorough cleaning to remove all traces of emulsion, allowing for reuse in future prints. Large-scale operations might opt for special cleaning liquids or acid baths, while others may find a water trough or sink with a power hose sufficient for cleaning their screens.

Frequently Asked Questions (FAQs):

Will screen printing ink rinse?

A garment properly screened by trained professionals using heat-treated washable ink should not fade. Following the manufacturer's instructions for ink drying temperature and time is crucial for producing a durable, washable item.

Screen Printing vs. Digital Printing:

Digital printing, specifically Direct-to-Garment (DTG), employs a fabric printer similar to an inkjet printer for direct image transfer onto fabric. Unlike screen printing, digital printing requires minimal setup, making it a cost-effective option for smaller batches. The process allows for detailed and colorful designs, with multiple colors applied simultaneously.

Silkscreen Printing vs. Heat Transfer:

Heat transfer printing relies on heat to bind a design to fabric, offering simplicity and affordability. Ideal for smaller batches and intricate designs, heat transfer can produce results on challenging items like bags and hats. Combining heat transfer with digital techniques offers versatility, though quality may vary based on materials and printing methods.

In conclusion, understanding the nuances of each component in screen printing equipment is crucial for achieving optimal results in your printing endeavors. From choosing the right press to experimenting with inks and perfecting the silkscreen, this guide aims to be your go-to resource for mastering the intricate and rewarding world of screen printing.

About the Creator

Screen Print Direct

Screen Print Direct: Partnering with printers & artists to achieve goals. A diverse team of printers, artists, students, & entrepreneurs with BIG ambitions. We aim to help YOU succeed.

Comments

There are no comments for this story

Be the first to respond and start the conversation.