How Can Additive manufacturing Be Integrated to E-Commerce Supply Chains

Additive manufacturing and ecommerce have a great deal of synergy. From Helping brands to innovate better to reducing time-to-customer, reducing cost, and boosting sustainability, there is a lot that AM can offer to ecommerce manufacturers. Here's a quick primer on all the ways. AM can help online retailers unlock more value from their supply chains.

Ecommerce has grown by leaps and bounds over the last few years. The rapid influx of brands online in the aftermath of the pandemic, as well as changing consumer behavior, has accelerated ecommerce growth significantly. The sector is now worth over $6 trillion globally and by 2026, some 24% of retail purchases are expected to happen online.

All of this has inevitably put more pressure on supply chains to deliver on demand and sustain the momentum. As brands compete ever more fiercely on not just price and quality, but also speed, supply chains are likely to be stretched more thinly in an effort to keep up.

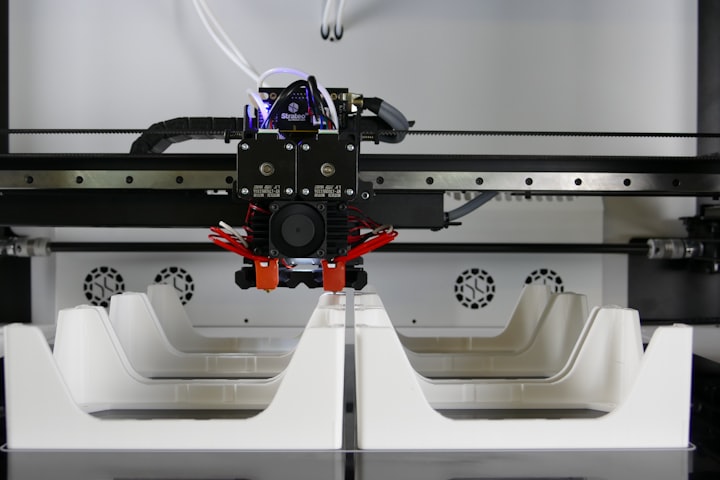

This is where additive manufacturing (AM), or 3D printing, can come in. As a flexible manufacturing solution that doesn’t necessarily depend on large facilities, AM is ideally suited to help companies manufacture more efficiently and reduce time-to-customer.

Supply Chain Disruptions

Demand-side pressures aren’t the only thing squeezing supply chains. Geopolitics has a lot to do with it as well. The conflict in Europe as well as that in the Middle East has limited shipping avenues for businesses. Not only that, it has contributed to global inflation with increased fuel costs, which in turn, influences how efficiently distributors can ship their goods.

Add to this the focus on renewables and sustainable manufacturing practices, all of which have left companies grappling for the resources they need. AM has the potential to alleviate many of these concerns.

AM and Ecommerce are Complementary

A lot of classic AM attributes, such as precision manufacturing and speed, are exactly what ecommerce providers are looking for. Companies across the board are investing into 3D printing to give themselves more options to satisfy customer demand without compromising on product quality. Here’s why this trend is likely to continue.

Speed

3D printing has proven to be a boon for small-scale producers. Typically, micro, small, and medium enterprises (MSMEs) cater to buyers with smaller orders. These smaller batch sizes mean they’re often offered poorer terms from their manufacturers who prefer larger orders. This raises the cost, which is passed on to the end-customer.

As a result of this, MSMEs struggle to compete with their larger counterparts and lose out on market share. Switching to 3D printing can help them recoup their last orders. One of the areas AM excels is small-batch production. In fact, it can reliably outperform traditional manufacturing techniques, including injection molding and CNC, when it comes to smaller batches.

Customization

The defining advantage of additive manufacturing is that it allows you a lot of flexibility with the design of your products. A 3D printer’s robotic arm can approach a product from any angle, achieving exactly the kind of design you’re looking for. Complex geometric shapes, such as a triple helix or a netted canister, are easy to achieve, at no extra cost.

With conventional manufacturing, you’d require a combination of techniques, including complex molds, subtractive machining, and hand finishing to achieve the same results. This tends to drive up both costs and time, all of which ultimately makes your products less attractive for your customers.

Versatility

As 3D printing technology evolves, businesses are finding newer applications for it. One of the driving forces of this has been materials innovation. Traditionally, AM companies have tended to use plastics, such as polymers, for their products. However, in recent years, advancements have allowed them to diversify into newer, more versatile materials.

This includes metal powders, ceramics, glass, concrete, hybrid composites, and more. This, in turn, has opened up newer avenues for additive manufacturing. 3D printing is now deployed in spaces, such as automotive manufacturing, aerospace, medical research and therapy, architecture, real estate, as well as consumer goods. Naturally, this benefits the ecommerce space as more brands can now leverage 3D printing for their own products.

Low Startup Cost

Conventional techniques, such as injection molding and metal casting, typically require a unique mold to mass produce a product. Hot plastic or metal is poured into this mold and cooled to deliver the finished product. Hence the term “injection molding.”

However, this can be a very tricky process for businesses that are manufacturers as well as innovators. Prototyping any product requires multiple iterations, including design iterations, to get it right. This is especially true with precision hardware manufacturing. With injection molding, this approach can significantly drive up costs as manufacturing a new type of mold and doing a run with each is expensive.

With 3D printing, you have a startup cost of 3D printers and scanners and you can use the hardware to iterate as many times as you like and offer consumers newer products that deliver greater value.

Decentralized Manufacturing

One of the biggest advantages of AM and e-commerce supply chains is the ability to decentralize manufacturing. With conventional manufacturing, producers make the most money on large orders that often need to be placed well in advance. The manufacturers also have to account for storage and inventory, which adds to the cost of the product.

With 3D printing, the hardware is often much smaller, especially with desktop printers that can fit in a closet. This means that instead of having one manufacturer that is far away from most of your customers, you can have multiple manufacturers that are closer to your customers, affording you more flexibility and improved speed in delivering orders.

Sustainable Manufacturing

All-in-all, additive manufacturing is a much more eco-friendly approach to manufacturing, given its on-demand, on-location nature. There tends to be less wastage with small-batch production and the ease of prototyping that 3D printing brings. Also, when the producer is closer to the customer, it helps optimize supply chains and production capacity, while saving fuel and materials.

Furthermore, in recent years, additive manufacturing has seen a big push into diversification away from materials like polymers and into bio-plastics and other sustainable materials.

Increasingly, additive manufacturing is seen not as an “alternative” manufacturing approach, but often the preferred method, particularly when it comes to prototyping and manufacturing creative designs. It has the potential to have a transformative impact on ecommerce supply chains and help brands reimagine the sales process for their customers.

About the Creator

Tess DiNapoli

Tess DiNapoli is an artist, freelance writer, and content strategist. She has a passion for yoga and often writes about health and wellness, but also enjoys covering the fashion industry and world of fitness.

Comments

There are no comments for this story

Be the first to respond and start the conversation.