MODERN TECHNOLOGY IN MECHANICAL ENGINEERING

TRENDING TECHNOLOGY IN MECHANICAL ENGINEERING

Modern technology has had a significant impact on the field of mechanical engineering, leading to the development of new and improved systems, machines, and processes. Some examples of

modern technology in mechanical engineering include:

1.3D Printing: This technology allows for the rapid prototyping and manufacturing of complex parts and structures, making it possible to create unique designs and custom components.

2.Robotics: Robotics technology has advanced significantly in recent years, leading to the development of more sophisticated and capable robots for use in manufacturing, transportation, and other industries.

3.Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM): These technologies allow for the creation and simulation of designs on a computer before they are built, and for the automation of manufacturing processes.

4.Advanced Materials: The development of new materials, such as composites and nanomaterials, has led to the creation of stronger, more durable and lightweight mechanical systems.

5.Sensors and IoT: The integration of sensors and the Internet of Things (IoT) technology into mechanical systems allows for real-time monitoring and control of equipment, leading to improved efficiency and maintenance.

6.Smart Factories: Smart factories utilize automation, IoT, big data analytics and machine learning technologies to improve the overall performance of the manufacturing process.

7.Mechatronics: The integration of mechanical, electrical, and computer engineering to create systems that are more efficient, precise, and intelligent.

These technologies are being used to create new products, improve existing products and increase the overall efficiency of mechanical systems.

1.3D Printing:

3D printing, also known as additive manufacturing, is a technology that allows for the creation of three-dimensional objects by building them up layer by layer. This is in contrast to traditional manufacturing methods such as

machining, casting, and molding, which involve cutting away material to create an object. There are several different types of 3D printing technologies, each with their own strengths and weaknesses.

Some of the most common include:

a.Fused Deposition Modeling (FDM):

This is the most widely-used 3D printing technology. It works by heating a filament of plastic or other material, and then extruding it through a nozzle to build up the object layer by layer.

b.Stereolithography (SLA):

This technology uses a laser to cure layers of liquid resin, creating a solid object. SLA prints are known for their high accuracy and detail, but they are typically more expensive than FDM prints.

c.Selective Laser Sintering (SLS):

This technology uses a laser to fuse together small particles of plastic, metal, or other materials. SLS is known for its ability to create complex and detailed objects, but it can be more expensive than other technologies.

d.Multi Jet Fusion (MJF):

This technology uses a print head that melts particles of plastic and fuses them together layer by layer, creating a solid object.

These are just a few examples of the many different types of 3D printing technologies available today. Each has its own advantages and disadvantages, and the best choice for a given project will depend on the desired properties of the final object, the cost, and the available equipment.

3D printing is used in a wide range of industries and applications, from prototyping and product development, to manufacturing and even medical fields like organ printing. It has the potential to revolutionize the way we make things, by allowing for faster, cheaper, and more efficient

production of complex objects.

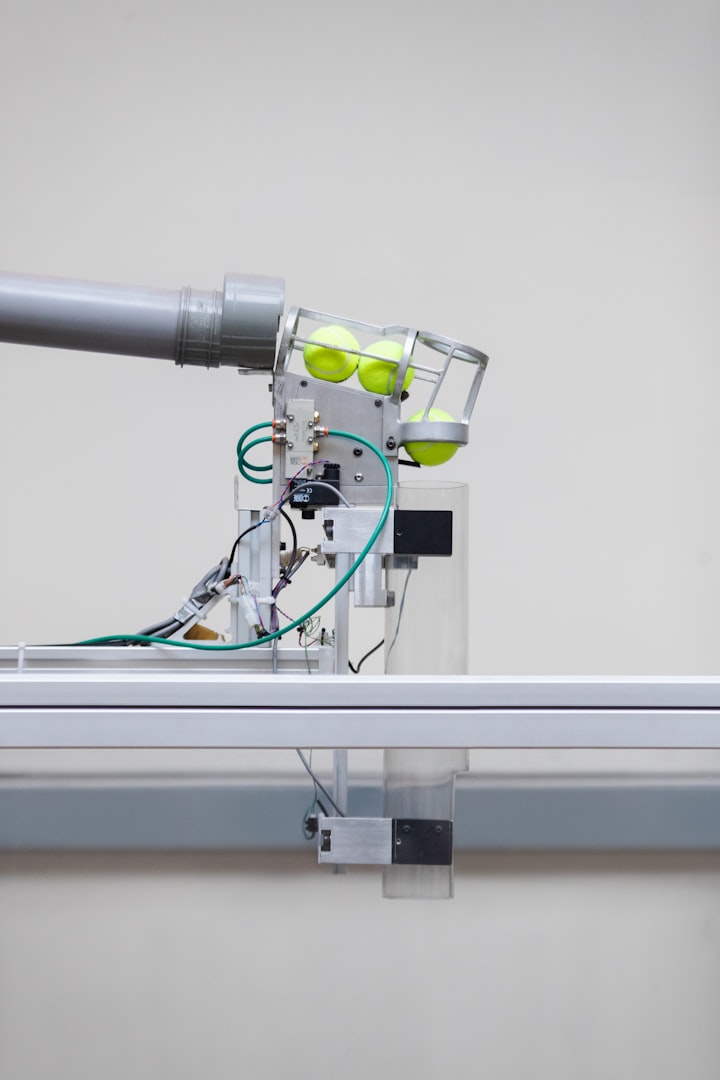

2.Robotics:

Robotics is the branch of engineering that deals with the design, construction, operation, and use of robots. Robots are machines that can be programmed to perform a variety of tasks, from simple repetitive actions to complex, sophisticated operations.

Robotic systems can be broadly categorized into two types: industrial robots and service robots. Industrial robots are typically used in manufacturing and other industrial settings, where they perform tasks such as welding, painting, and assembly. Service robots,

on the other hand, are designed to interact with humans and assist them in a wide range of tasks, such as cleaning, cooking, and healthcare.

Robotic systems are typically composed of several key components:

a.Actuators: which provide the robot's movement and force

b.Sensors: which gather information about the environment and the robot's state

c.Control systems: which process information from the sensors and use it to control the actuators

d.Programming: which determines how the robot will react to different inputs and situations

Robotics technology has been advancing rapidly in recent years, and robots are becoming more sophisticated, capable, and versatile. Robotics applications are widely used in manufacturing, health care, logistics, transportation, and other fields.

Robotics is also being used in the field of Artificial Intelligence, where AI-driven robots can learn from their interactions with humans, making them more efficient and adaptable. The field of robotics is interdisciplinary, combining knowledge from

mechanical engineering, electrical engineering, computer science, and other fields. As robotics technology continues to evolve, it is expected to play an increasingly important role in many areas of society, and researchers are working to develop

new and innovative ways to use robots to improve people's lives.

3.Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM):

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) are both computer-based technologies that are used in the design and production of products.CAD is a software that allows engineers, architects, and other professionals to

create detailed 2D and 3D models of products, buildings, and other structures. It enables the user to create, edit, and modify designs on a computer, rather than manually drawing them. CAD software can also be used to simulate the performance of a

design, to check for errors and identify potential problems before it is built. CAM, on the other hand, is software that is used to control machine tools and other manufacturing equipment. It allows manufacturers to create detailed instructions for the

machines to follow, so that they can produce parts or products according to the specifications of the CAD design. CAM software can also be used to optimize the production process, to minimize costs and improve efficiency. CAD and CAM systems are often

integrated, allowing engineers to move seamlessly from design to production. The use of CAD and CAM technologies has enabled manufacturers to design and produce products more quickly, accurately and cost-effectively. They are widely used in a variety

of industries such as manufacturing, aerospace, automotive, and architecture. CAD and CAM technologies are constantly evolving, with new features and capabilities being added all the time. For example, some CAD software can now simulate the physics of real-world materials,

allowing designers to see how a product will behave under different conditions, and some CAM software can now generate code for 3D printing.

4.Advanced Materials:

Advanced materials are materials that have been engineered to have specific properties or characteristics that make them suitable for specific applications. These materials have unique properties such as strength, conductivity, and durability that

make them suitable for a wide range of applications in various industries.

There are many different types of advanced materials, including:

a. Nanomaterials: Materials that are made up of tiny particles on the nanometer scale. These materials have unique properties such as high strength and high conductivity, making them useful in electronics, energy storage, and biomedical applications.

b. Composites: Materials made up of two or more different materials, such as carbon fiber reinforced plastic (CFRP) which is a composite of carbon fibers embedded in a plastic matrix. These materials have high strength-to-weight ratios and are used in aerospace, automotive, and construction applications.

c. Smart materials: Materials that can change their properties in response to external stimuli such as temperature, light, or pressure. These materials are used in a wide range of applications such as sensing, actuation, and energy conversion.

d. Biomaterials: Materials that are derived from natural sources such as proteins, carbohydrates, and lipids, or that mimic the structure and function of natural materials. These materials are used in medical and dental implants, tissue engineering, and drug delivery.

e. Graphene: is a single layer of carbon atoms arranged in a hexagonal lattice and it is known for its exceptional mechanical, electrical, and thermal properties. It can be used in various applications such as electronics, energy storage, and biomedical applications.

Advanced materials have the potential to revolutionize many different industries by enabling the development of new products and technologies. As research in this field continues to advance, it is likely that we will see more and more novel applications of advanced materials in the future.

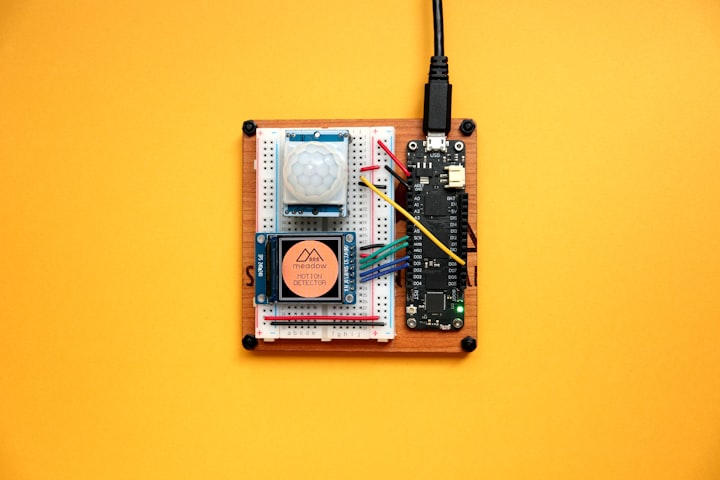

5.Sensors and IoT:

Sensors and the Internet of Things (IoT) are closely related technologies that are being used to collect and transmit data from the physical world to the digital world. A sensor is a device that can detect and respond to a physical stimulus, such as light, temperature, or motion.

Sensors are used in a wide range of applications, including medical devices, industrial automation, and consumer electronics.

Some examples of sensors include:

a.Temperature sensors: detect temperature and convert it into an electrical signal that can be interpreted by a computer or other device.

b.Light sensors: detect the intensity and color of light and convert it into an electrical signal.

c.Motion sensors: detect movement and convert it into an electrical signal.

d.Pressure sensors: detect the force applied to a surface and convert it into an electrical signal.

The Internet of Things (IoT) refers to the network of physical objects, such as devices and appliances, that are embedded with sensors and connected to the internet. These devices can collect data from the environment and transmit it to the cloud or other devices for analysis, control, and automation.

By connecting sensors to the Internet, they can be accessed remotely and their data can be analyzed and acted upon. For example, temperature sensors in a building can be used to automatically adjust the heating and cooling systems, or motion sensors can be used to detect when a room is occupied and turn on the lights.

The IoT is expected to have a huge impact on many different industries, from healthcare to transportation, by enabling the development of new products and services that can improve efficiency, reduce costs, and improve the quality of life. The increasing popularity of IoT and the growing number of connected devices are expected

to drive the demand for sensor technology in the future.

6.Smart Factories:

A smart factory is a highly digitized and connected industrial facility that uses advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and robotics

to optimize manufacturing processes and improve efficiency, quality, and flexibility. Smart factories typically have systems in place for monitoring and controlling all aspects of production,

from raw materials and supply chain management to equipment and production lines, and can make real-time adjustments to improve performance and reduce downtime. Additionally, smart

factories can use data analysis and machine learning to predict and prevent maintenance

issues and improve overall production planning.

7.Mechatronics:

Mechatronics is the combination of mechanical engineering, electrical engineering, and computer science to design and control advanced systems and machines. Mechatronics systems

often incorporate a variety of sensors, actuators, and control systems to achieve a specific function or set of functions, such as robotics, automation, and advanced manufacturing systems.

The goal of mechatronics is to create systems that are more efficient, reliable, and adaptable than those that rely on mechanical or electrical systems alone. Mechatronics systems are used in

a wide range of applications such as in automotive, aerospace, medical equipment, and industrial automation, home appliances, and many more.

Comments

Dhivya Victor Doss is not accepting comments at the moment

Want to show your support? Send them a one-off tip.