What is the Difference Between NC and CNC Machines? Full Explained

In this article, we will learn about the distinction between NC and CNC machines. In this day and age, each assembling business needs high exactness items in less time. What’s more, this complicated world of high precision in the least time can be accomplished by the utilization of NC and CNC machines.

The vast majority of us don’t know the essential difference between these machines. Here we will talk about the essential contrasts among them. Before going to the basic difference you must know the comparison between NC and CNC machines. so now before going discuss the difference between NC and CNC machine, let discuss NC and CNC in detail.

NC machine

Numerical Control (NC) indicates, the strategy for controlling the assembling task by straightforwardly providing numerical codes into the machine device. Realize that it’s anything but a machining technique, rather, it is an idea of machine control.

In a Numerical Control machine, the program is fed to the machine through the punched card, attractive tapes, and other such media. The program comprises of exact guidelines about the manufacturing method just as the developments. It has no memory storing and it keeps running off of the “tape” each time the machine cycles.

The basic highlights of numerically controlled machines have been built up for a long time. They involve a controller, known as the machine control unit MCU, fit for perusing and interpreting a stored program and utilizing the directions in dis to control a machine by means of activation devices.

The full step by step commands directions that coordinate the activities of the processing called a program of instruction. In machine apparatus applications, the program of guidelines is known as a part program, and the individual who readies the program is known as a section developer.

In these applications, the individual commands refer to places of a cutting instrument in respect to the worktable on which the work part is installation. Extra instructions are generally included, for example, spindle speed, feed rate, cutting apparatus choice, and different capacities. The program is coded on an appropriate model for accommodation to the machine control unit.

In NC or numerical control machine, attractive tapes or punch cards are utilized to sustain the program into the machine. Prior numerical control machines were extremely fundamental in a world where apparatuses of the machine were changed or adjusted to be associated with engines so the development happens to be the same as or with the associated axes.

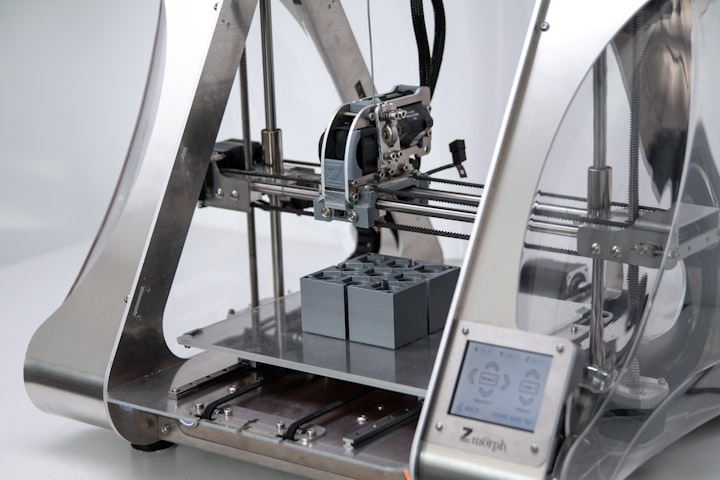

Computer Numerical Control (CNC) Machine

In a Computer Numerical Controlled machine, the machines are connected with computers. This makes them increasingly adaptable as in, assume an adjustment in the measurement of a section is required. In an NC machine, you would need to change the program in the tape, and after that feed it to the machine once more. However, in a CNC machine, you simply change a variable in the computer and you can adjust the program. It has memory storing and the program can be put away in its control.

In current CNC frameworks, the structure of a mechanical part and its manufacturing program is much robotized. The part’s mechanical measurements are characterized utilizing PC helped plan (CAD) programming and afterward converted into manufacturing commands by computer-aided manufacturing (CAM) programming.

The subsequent commands are changed (by “post processor” programming) into the particular directions vital for a specific machine to deliver the segment, and afterward fixed into the CNC machine. Comprises of primary memory and auxiliary memory. Principle memory (Primary storage) comprises ROM (read-only memory) and RAM (Random access memory) devices.

Numerical control part programs are put away in RAM devices. The Current program in RAM can be removed and displaced by the new program as works are changed. High-limit optional memory (additionally called helper storing or auxiliary storing) devices are utilized to store expansive programs and information records, which are exchanged to fundamental memory as required. In NC machine if a mistake happens in the program than it's investigating and adjustment isn’t simple. In the CNC machine, the troubleshooting and alteration are simple.

Difference Between NC and CNC Machine

- Input data method: Punched tape, punched card, and other such media.Input data method: programs are fed directly into the computer by a small keyboard similar to our traditional keyboard.

- NC machine cost is less. NC machine cost is high.

- Programs should be changed in the punched card and then fed to the machine. We can modify the program on a computer.

- Flexibility is less. Flexibility is high

- It required more time to perform an operation. It requires less time.

- It is known as the machine which is controlled by the set of instructions in the form of numbers, letters, and symbols. The set of instructions is called a program. It is known as the machine which is used to control the motions of the workpiece and tool with the help of a prepared program on the computer. The program is written in alphanumeric data.

- Modification in the program is difficult. Modification in the program is very easy.

- It is not possible to run it continuously. It can be run continuously for 24 hours a day.

Correlation Between NC and CNC Machine

- NC represents Numerical Control while CNC represents Computer Numerical Control.

- The programs are fed into the punch cards in NC machines but in other cases, in CNC machines the programs are provided specifically into the PC with the assistance of a little keyboard similar to our conventional keyboard.

- In NC machine if a mistake happens in the program than it’s investigating and adjustment isn’t simple. Hence in the CNC machine, the troubleshooting and modification are simple.

- NC machine requires a talented operator though to work a CNC machine, a semiskilled administrator may work because CNC is a bit difficult to operate.

- The cost of the NC machine is less as compared and the CNC machine.

- The maintenance cost of NC is less than a CNC machine.

- NC machine cannot keep or store any program. CNC machines can store quantities of programs and thus can utilize over and over for the creation.

- The precision of the NC is less as contrasted and the CNC.

- In the NC machine the execution of the job takes additional time but in the CNC machine executes the job without taking much time. Thus NC machines take more time than CNC machines.

- NC can’t run constantly for 24 hours however on the other hand CNC machine can run for 24 hours persistently.

So it is clear from the above discussion that the CNC machine is better than NC. Because CNC is more flexible than NC but NC has its own advantages over CNC.

About the Creator

A

I write my heart out here. My posts are informational and something I do great research for SEO before writing it. Follow me on Twitter: Aamir Twitter,

Comments

There are no comments for this story

Be the first to respond and start the conversation.