CNC Machining: All You Need To Know!

Custom CNC machining

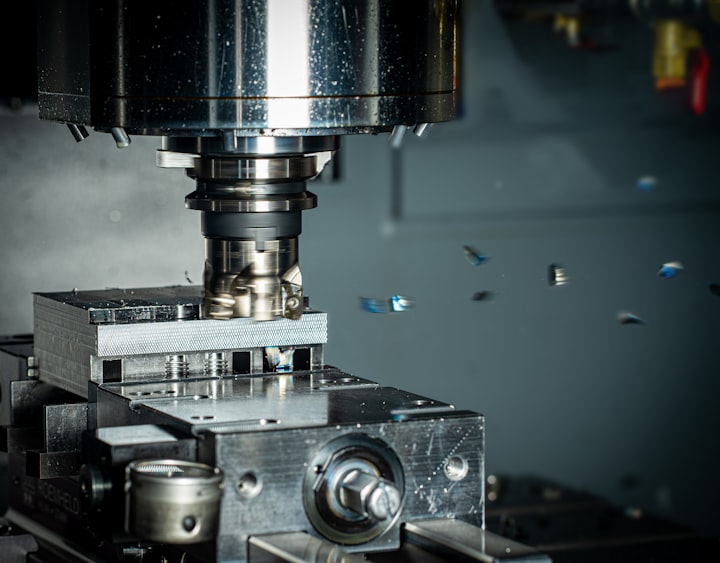

CNC machining is developing, as are the processes used to produce machined components. Customers want accurate parts. And it is all feasible to accomplish the desired result using the procedures. Custom machining is one such procedure. It refers to a bespoke machining technique to satisfy customer needs.

Let's talk about bespoke machining and why machine shops prefer it.

What is custom machining?

The CNC machining process includes custom machining. Machinists can use several CNC machining forms to manufacture a new part in custom machining. When a particular component is not available at the machine shop, custom machining is necessary. They can then use custom CNC milling machining services to make the component. When a common item has a unique requirement, custom machining is necessary. And bespoke machining is not limited to the production of small things.

However, it is also possible to design significant portions with several characteristics. These parts are tailored to match a specific project.

Here are some examples of custom CNC machining used to make parts:

- CNC milling: CNC milling is used by machinists to turn and drill metals. Other materials are treated in the same way.

- CNC turning: Another standard custom machining method is CNC turning. A metal rod is spun by a CNC-controlled cutting tool during CNC turning. To make a finished product, the device eliminates pieces of metal.

- CNC router: Metal sheets are cut into elaborate shapes using a CNC router. It is also used to provide extensive CNC custom machining services.

Why use Custom CNC Machining?

CNC machines may be used without sacrificing quality. Unlike physical labor, where there is always the possibility of mistake.

Here are some of the benefits of employing custom machining:

Parts of high quality and accuracy

CNC machining aids in the manufacturing of difficult-to-manufacture applications. Even with tiny diameters, CNC production's high accuracy capabilities assure you receive exactly what you need.

Custom machining assists in producing the same item again and over till the last part is created.

Custom components must be manufactured

At some point, your equipment will require specialized production of parts. It comprises jobs with a short turnaround time that need additional components and materials. Unindividual arts that are not available in manufacturer catalogs be requested for projects.

Production on time

During CNC custom machining, raw materials must be eliminated in order to obtain the proper form. A mistake is less likely to occur when producing machined components because the CNC machine is programmed to follow the proper instructions.

Machine shops are capable of working with rigid materials

Some materials cause issues throughout the manufacturing process. Plastic is one such material that necessitates the use of specialized CNC machining equipment. Furthermore, certain metals, such as bronze and stainless steel, require specific components and equipment. These materials cannot be used traditionally and provide the required results.

Reasons for custom machining

When a machinist assembles several pieces into a single item, the client may require a sophisticated part in some cases. Manufacturing a particular item now needs greater accuracy and a variety of factors.

In an emergency, high-quality components are manufactured. Precision components are in high demand in numerous areas, including aerospace, military, and medical. Bespoke machining speeds up the production of high-quality goods. Machine shops are capable of producing tiny volumes. Most manufacturing businesses use custom machining to machine products to your specifications.

Industries that require CNC machining

Every industry requires custom-made machining, and the businesses also need accurate parts.

These are the industries where CNC machines are widely used:

- Aerospace industry

- Agriculture industry

- Automotive industry

- Construction industry

- Firearms industry

And many more.

See Related:

Comments (1)

This is now the easiest way to quickly get spare parts for various purposes, devices, businesses, repairs, products. For example, I was renovating a house and needed unique furniture parts. On the website https://machiningtoday.com/cnc-machining-services/ I was able to quickly create the necessary clamps according to my drawing