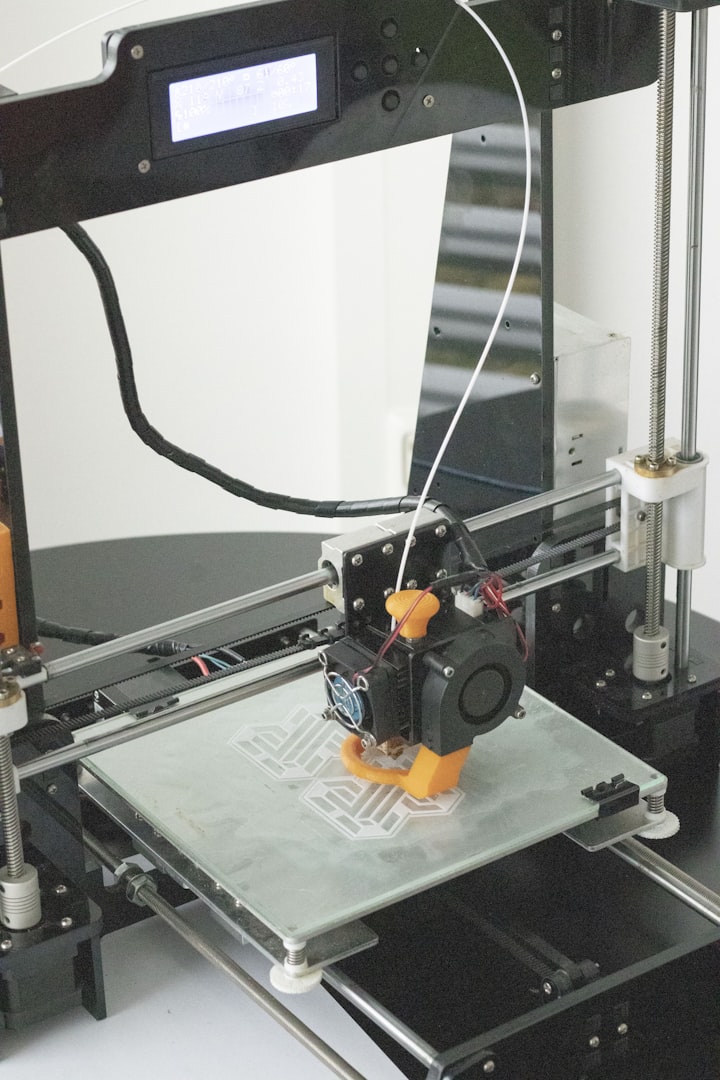

Like its predecessors, the Prusa i3 MK3 is a smaller version of the original Prusa I3 Mk3 but the print quality is comparable and the size is very manageable. It comes in an easy way to integrate and uses Fused Deposition Modeling (FDM) to convert standard modeling materials such as PLA, PETG, ASA, ABS, and Flex into precise printed products. Its quick setup is the quietest printer we have ever tested, and it is compatible with a wide variety of plastics.

Sarah Tew / CNET In this model I have used the best 3D printer that measures price, ease of use, and quality of printing. Windows Central Review Team Prusa Research has created something special with its original Prusa i3-MK3. They carry a lot of good features and the cost of printing is very low.

You can use a standard 17.5 mm PLA filament used by most 3D printers, or you can use a 3 mm fiberglass box made of various materials. Dan Ackerman / CNET There is a small version of a large industrial 3D printer format, but it is a dual-extruder printer that means it can use two different commodity communities. This allows you to print two copies simultaneously, using two different colors to create multi-colored 3D objects.

Since each material has a different melting point, the use of external fibers is limited to printers that are designed or that have software that allows the user to control the temperature of the extruder. SLA printers with liquid particles use strong fibers, so more time is needed to repair and print what may not be compatible with other users. Some 3D printers have multiple extruders to print objects in two or more colour.

Our professional 3D printers produce high-quality 3D printed components from high-quality 3D printed materials such as PLA, ABS, ASA, PETG, TPU, PC, PA12 CF (also known as nylon, polyamide 12, and reinforced carbon fiber). Learn more about building materials that you can use for 3D printing on our 3D printers page. This list of materials and technologies makes Form 3D one of the most diverse 3D printers on the market.

Resin printers are the next step in Rapid Prototyping and Design technology if you want to meet your printers to look classy and meet in the factory. The 3D printer pulls out a series of thin layers of molten plastic according to the coded instructions in the file for printing. Form-3 is the smallest attractive feature of its entire machine and uses the most accurate laser to ensure unmatched print quality that surpasses that of FDM printers.

3D printed objects are made using an add-on method. In this process, the equipment is placed in a small diameter tube in drops such as standard inkjet and paper printers and a layer layer used on the construction platform, under UV light. In additional printing, the resulting object is placed in successive layers of object.

With this type of technology, no additional vertical support structure (D) is required to maintain partial overlap and a fixed 3D printing representation is known as the production of a soluble film in which a plastic strip is inserted into the hot movable melting head and out. string, placing it horizontally in the shape you want. Direct refers to the construction of objects with 3D design, and indirect production means that material samples can be printed and used for mold or investment testing. This allows custom printing of shapes and changes in memory.

The term 3D printing refers to the process by which a material-bound bond is layered horizontally in a powder bed on the head of an inkjet printer. It refers to polymer technology and, in any sense, the umbrella name for additional production, which may be used in metal environments and for the production of end pieces for lovers of polymer, inkjet, and stereolithography. Multi-material 3D printing solves this problem by making it possible to produce objects with complex and varied material layouts with a single printer.

One limitation is that 3D printers with multiple ads can print multiple objects, but multicolor print file format separates file color areas with different colors to fit a three-dimensional puzzle. Depending on the nature of the situation, an SLA may require the use of support structures. Businesses involved in producing small quantities may require larger building space to print more items.

Some 3D printers use stereolithography, the first 3D printing method developed by ultraviolet (UV) lasers, that trace patterns in a liquid-coating frame that then hardens into a substance. In Rapid Shell Modeling (RSM), the technician uses silicone to make the ear canal marker, and the text is scanned with small specimens in the model, and then printed on resin by a 3D printer.

A little more processing is needed, as the parts are printed with FFF technology and the supporting structure should be removed if necessary. If you get a good 3D printer and end up being a slave to 3D printing and add-on production, don't blame me. You can use it to build complete products, produce backup parts and make things you find useful at the home, office, or workplace.

As shown in the chip test, Prusa thoroughly tested the first Prusa i3 and MK3. The printer works well for beginners and is powerful enough for advanced users. FlashForge is designed for schools and education and is easy to use.

Comments

There are no comments for this story

Be the first to respond and start the conversation.